A 3D printer is a type of machine that can create physical objects by layering material on top of each other, based on a digital 3D model. The printer uses a process called additive manufacturing, which involves depositing material layer by layer until the object is complete.

Most work by melting plastic filament, which is then extruded through a heated nozzle to create the object. Some can also use other materials, such as metal or resin, to create more complex objects.

Here are some of the most common types:

- Fused Deposition Modeling (FDM): FDM is the most common type of 3D printing technology. It uses a filament of thermoplastic material, which is melted and deposited layer by layer to create the final object. This method is affordable and relatively easy to use, making it popular among hobbyists and makers.

- Stereolithography (SLA): SLA uses a liquid resin that is cured by a laser to create the final object. The printer creates the object layer by layer, with each layer being cured by the laser. This method can produce highly detailed and accurate objects but requires more advanced equipment and materials.

- Digital Light Processing (DLP): DLP is similar to SLA, but instead of using a laser to cure the resin, it uses a digital projector to project a pattern onto the resin to cure it. This method can also produce highly detailed and accurate objects but is typically faster than SLA.

- Selective Laser Sintering (SLS): SLS uses a laser to selectively melt a powdered material, typically nylon, to create the final object. This method can produce strong and durable objects with complex geometries but requires more advanced equipment and materials.

- Binder Jetting: Binder Jetting uses a liquid binder that is selectively deposited onto a powdered material, typically metal or ceramic, to create the final object. The object is then sintered in an oven to fuse the powdered material together. This method is commonly used in industrial applications but is not commonly used for hobbyist 3D printing.

Each type of printer has its advantages and disadvantages, and the choice of printer depends on the specific needs and requirements of the user.

3D printing technology has many applications, including prototyping, product design, architecture, medicine, and even art. With one, you can create almost any object you can imagine, from a small toy to a large scale model.

There are several available in the market that are priced under $200. Here are some options that you could consider:

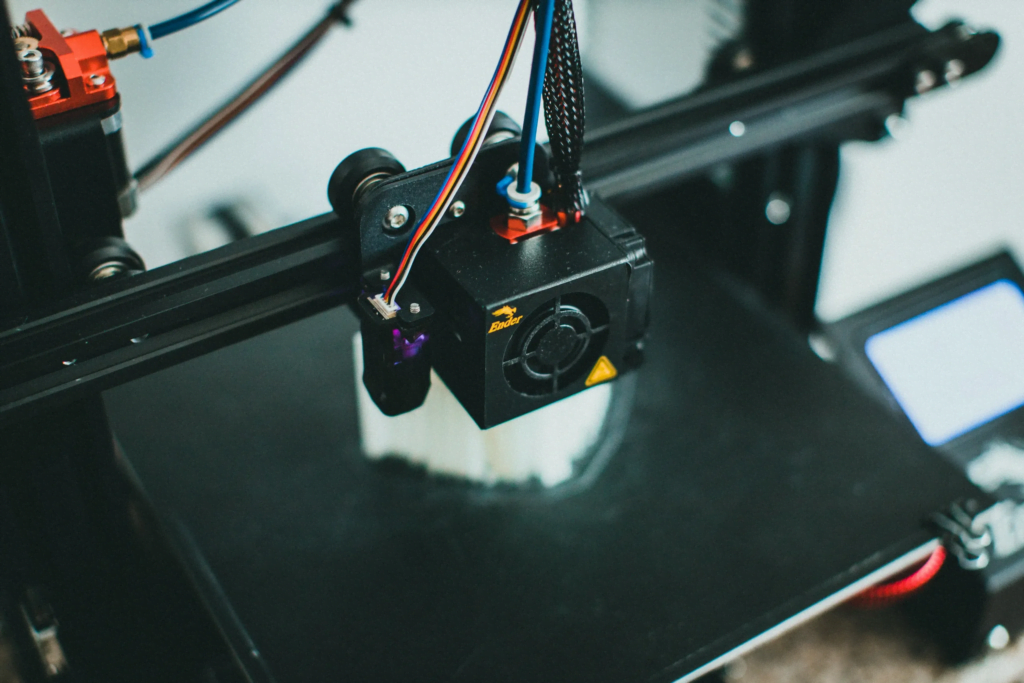

- Creality Ender 3: The Creality Ender 3 is a popular budget 3D printer that has a build volume of 220 x 220 x 250mm. It features a heated bed, a resume printing function, and supports multiple filaments. The printer has a sturdy frame and is relatively easy to assemble. Get it Here

- Anycubic Kobra Neo: The Anycubic Kobra Neo is another popular budget 3D printer that has a build volume of 250x 220x 220mm, . It features a heated bed, auto-leveling bed, and an optional filament run-out sensor. The printer has a metal frame and is easy to assemble. Get it Here

- Comgrow Creality Ender 3 Pro: The Comgrow Creality Ender 3 Pro is a slightly upgraded version of the original Ender 3. It features a more stable frame, a magnetic bed, and a Meanwell power supply. The printer has a build volume of 220 x 220 x 250mm and supports multiple filaments. Get it Here

To see a larger selection of 3D Printers that are $200+, check them out Here

All of these printers are popular among hobbyists and makers due to their affordability and ease of use. However, keep in mind that 3D printing requires some knowledge and patience, and these printers may require some tweaking and calibration to get the best results.